Key Takeaways

| Question | Answer |

|---|---|

| What is a PLC? | A Programmable Logic Controller (PLC) is an industrial digital computer that monitors inputs and outputs to make logic-based decisions for automated processes. |

| What is an Anybus Gateway? | An Anybus Gateway is a device that enables communication between different industrial networks, facilitating data exchange between devices like Siemens PLCs. |

| Why connect Siemens PLCs using Anybus? | Connecting Siemens PLCs with Anybus gateways enhances interoperability, expands connectivity options, and simplifies integration with various industrial networks. |

| Which protocols are used? | Common protocols include Profinet and Modbus TCP. |

| Steps to connect using Profinet? | 1. Gather hardware and software 2. Configure network settings 3. Connect PLCs and gateways 4. Test the connection |

| Steps to connect using Modbus TCP? | 1. Gather hardware and software 2. Configure network settings 3. Connect PLCs and gateways 4. Test the connection |

| Expert Tips? | Optimize performance, ensure data synchronization, and implement security measures. |

| Troubleshooting Tips? | Resolve connectivity issues, correct configuration errors, and address performance problems. |

| Recommended Products? | Anybus X-gateways, Anybus Communicator, Siemens PLC models such as S7-1200 and S7-1500. |

1. Introduction

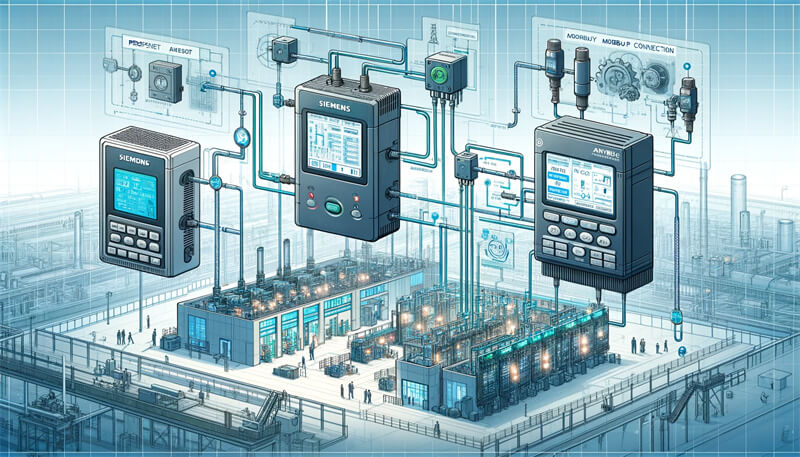

In the rapidly evolving world of industrial automation, the ability to connect multiple Siemens PLCs efficiently is crucial for maintaining smooth and productive operations. Established in 2013, ControlNexus is a leading provider of Siemens PLCs, HMIs, and inverters. This comprehensive guide will walk you through the process of connecting two Siemens PLCs using Anybus gateways, offering step-by-step instructions, expert tips, and practical solutions.

2. Understanding the Basics

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial digital computer designed to perform control functions. PLCs, such as those offered by Siemens, are used to monitor inputs and outputs and make decisions based on programmed logic to automate industrial processes. Learn more about the different Siemens PLC models and their applications.

What is an Anybus Gateway?

An Anybus Gateway is a powerful device that enables communication between different industrial networks. It acts as a bridge, facilitating data exchange between devices that use different communication protocols. This capability is essential for integrating Siemens PLCs with other systems, enhancing interoperability, and expanding connectivity options.

3. Connectivity Options

Profinet

Profinet is a leading industrial Ethernet standard for automation, offering high-speed communication and robust performance. It is widely used in Siemens PLC networks for its efficiency and reliability.

Advantages of Using Profinet:

- High data transmission speed

- Real-time communication capabilities

- Easy integration with existing Siemens systems

Modbus TCP

Modbus TCP is another popular protocol used for connecting industrial devices. It is a version of the Modbus protocol that uses TCP/IP for communication, making it suitable for integrating devices over Ethernet networks.

Advantages of Using Modbus TCP:

- Simple and flexible communication

- Wide compatibility with various devices

- Cost-effective integration solution

4. Step-by-Step Guide

Connecting Two Siemens PLCs Using Profinet

Requirements

- Siemens PLCs (e.g., S7-1200, S7-1500)

- Anybus Profinet Gateway

- Configuration software (e.g., TIA Portal)

Configuration Steps

- Gather Hardware and Software:

- Ensure you have the necessary Siemens PLC models and an Anybus Profinet Gateway.

- Install the TIA Portal software for configuration.

- Configure Network Settings:

- Open TIA Portal and create a new project.

- Add the Siemens PLCs and Anybus Gateway to the project.

- Configure IP addresses and Profinet settings.

- Connect PLCs and Gateways:

- Physically connect the PLCs to the Anybus Gateway using Ethernet cables.

- Ensure all devices are powered and properly connected.

- Test the Connection:

- Use the diagnostic tools in TIA Portal to verify the connection.

- Check for any errors and ensure data is being transmitted correctly.

Connecting Two Siemens PLCs Using Modbus TCP

Requirements

- Siemens PLCs (e.g., S7-300, S7-400)

- Anybus Modbus TCP Gateway

- Configuration software (e.g., TIA Portal)

Configuration Steps

- Gather Hardware and Software:

- Ensure you have the necessary Siemens PLC models and an Anybus Modbus TCP Gateway.

- Install the TIA Portal software for configuration.

- Configure Network Settings:

- Open TIA Portal and create a new project.

- Add the Siemens PLCs and Anybus Gateway to the project.

- Configure IP addresses and Modbus TCP settings.

- Connect PLCs and Gateways:

- Physically connect the PLCs to the Anybus Gateway using Ethernet cables.

- Ensure all devices are powered and properly connected.

- Test the Connection:

- Use the diagnostic tools in TIA Portal to verify the connection.

- Check for any errors and ensure data is being transmitted correctly.

5. Expert Tips and Best Practices

Optimizing Performance

- Ensure that the network settings are properly configured to prevent data collisions and ensure smooth communication.

- Regularly update firmware and software to take advantage of the latest performance improvements and security patches.

Data Synchronization

- Use synchronization protocols to ensure data consistency between the connected PLCs.

- Implement periodic checks to verify that data is accurately synchronized across the network.

Security Considerations

- Implement network security measures such as firewalls and secure passwords to protect against unauthorized access.

- Regularly audit and monitor network activity to detect and respond to potential security threats.

By following these steps and best practices, you can efficiently connect two Siemens PLCs using Anybus gateways, enhancing your industrial automation setup. For further guidance and expert advice, explore our comprehensive resources on Siemens PLCs and industrial automation solutions.

6. Troubleshooting Common Issues

Even with the best planning and setup, issues can arise when connecting Siemens PLCs using Anybus gateways. Here are some common problems and their solutions to help you troubleshoot effectively:

Connectivity Problems

- Unstable Connections:

- Solution: Check all physical connections to ensure cables are securely connected. Verify that all devices are powered on and properly configured within the network settings.

- Connection Failures:

- Solution: Verify IP addresses and subnet masks to ensure they are correctly configured. Check for IP address conflicts and ensure that each device has a unique IP address.

- Network Interference:

- Solution: Minimize electromagnetic interference by using shielded cables and keeping network cables away from high-power electrical lines.

Configuration Errors

- Incorrect Protocol Settings:

- Solution: Double-check the configuration settings in TIA Portal or any other configuration software. Ensure that the correct protocol (Profinet or Modbus TCP) is selected and properly configured.

- Software Mismatches:

- Solution: Ensure that all software, including firmware and configuration tools, are up to date. Incompatible versions can cause communication issues.

- Device Incompatibility:

- Solution: Verify that all devices, including the PLCs and Anybus gateways, are compatible with each other. Consult the product manuals for compatibility information.

Performance Issues

- Slow Data Transfer:

- Solution: Optimize network settings to improve data transfer rates. This can include adjusting the baud rate for serial communications or optimizing the network topology.

- High Latency:

- Solution: Reduce network congestion by segmenting the network or increasing bandwidth. Ensure that no unnecessary devices are connected to the network.

- Packet Loss:

- Solution: Check for network errors using diagnostic tools. Replace any faulty cables or connectors that may be causing packet loss.

By addressing these common issues, you can maintain a stable and efficient connection between your Siemens PLCs and Anybus gateways. For more detailed troubleshooting guides, visit our comprehensive resource page.

7. Product Recommendations

Choosing the right products is essential for successful integration. Here are some top recommendations for Anybus gateways and Siemens PLCs that ensure robust connectivity and optimal performance.

Recommended Anybus Gateways

- Anybus X-gateway:

- Features:

- Connect Siemens PLCs using Profinet with other PLC networks.

- Supports a wide range of industrial Ethernet and fieldbus networks.

- Benefits:

- Easy to set up with no programming required.

- Ensures seamless communication between different networks.

- Learn more about Anybus X-gateway

- Features:

- Anybus Communicator:

- Features:

- Converts non-networked devices to communicate over Profinet.

- Supports RS-232/422/485 or CAN-based devices.

- Benefits:

- Enables legacy devices to connect to modern networks without hardware changes.

- Simplifies the integration process with easy configuration.

- Discover the Anybus Communicator

- Features:

Recommended Siemens PLCs

- Siemens S7-1200:

- Features:

- Compact design with integrated IOs.

- Ideal for small to medium-sized automation tasks.

- Benefits:

- Flexible and scalable for various applications.

- High performance and easy integration with other Siemens devices.

- Explore the Siemens S7-1200

- Features:

- Siemens S7-1500:

- Features:

- High-speed backplane bus.

- Advanced diagnostics and communication capabilities.

- Benefits:

- Provides enhanced performance for complex automation tasks.

- Robust and reliable with extensive connectivity options.

- Discover the Siemens S7-1500

- Features:

By choosing the right combination of Anybus gateways and Siemens PLCs, you can ensure efficient and reliable connectivity for your industrial automation projects.

8. Case Studies and Real-World Examples

Case Study 1: Industrial Automation System

Scenario: A manufacturing plant needed to integrate new machinery into their existing production line, which used Siemens PLCs. The goal was to extend the production line without replacing the existing infrastructure.

Solution: The plant used Anybus X-gateways to connect the new machinery's PLCs with the existing Siemens PLC network. The integration was seamless, with no significant downtime during the setup.

Outcome: The plant successfully extended its production line, resulting in increased productivity and reduced operational costs. The use of Anybus gateways ensured compatibility and reliable communication between the new and existing systems.

Case Study 2: Retrofit Project

Scenario: A company needed to retrofit its legacy machines to communicate with modern Siemens PLCs without significant hardware modifications.

Solution: The company employed Anybus Communicators to enable the legacy machines to connect to the Siemens PLC network using Profinet. The retrofit allowed the legacy machines to send and receive data as part of the integrated system.

Outcome: The retrofit project was completed efficiently, enabling the company to modernize its operations without replacing costly legacy equipment. The Anybus Communicators provided a cost-effective solution for integrating old and new technologies.

These case studies demonstrate the versatility and effectiveness of Anybus gateways in various industrial scenarios, highlighting their ability to enhance connectivity and improve operational efficiency.

9. Additional Resources

For further information and support, explore the following resources:

- Further Reading:

- Training and Support:

10. Conclusion

Connecting two Siemens PLCs using Anybus gateways can significantly enhance your industrial automation capabilities. By following the detailed steps and best practices outlined in this guide, you can achieve seamless integration and optimize your operations. Explore our product offerings and resources to ensure successful implementation and ongoing support.

For any further assistance or inquiries, feel free to contact us. Our team at ControlNexus is dedicated to providing the best solutions for your industrial automation needs.

One Response

Heya! I’m aat work browsing your blog from my new iphone!Just wanted to

say I lve reading your blog and look forward to all

your posts! Keep up the great work! https://bandurart.mystrikingly.com/