Welcome to ControlNexus, your trusted partner for Siemens PLCs, HMIs, and Inverters. Established in 2013, we are committed to delivering top-notch industrial automation solutions. This article provides an in-depth look at organization blocks (OBs) in Siemens PLCs, essential components for efficient and reliable PLC programming.

Key Takeaways

| Question | Answer |

|---|---|

| What are organization blocks (OBs) in Siemens PLCs? | OBs are the interface between the PLC operating system and the user program, handling tasks like cyclic program execution, time interrupts, and event-driven processes. |

| What is the main cyclic OB1? | OB1 is responsible for cyclically executing the user program, ensuring continuous operation of the PLC logic. |

| Why are time interrupt OBs important? | They allow specific tasks to be executed at defined intervals, crucial for time-sensitive operations. |

| What role does OB100 play in Siemens PLCs? | OB100 is a start-up OB that initializes variables and checks system conditions before the main cyclic execution begins. |

| How do cyclic interrupt OBs (OB30) function? | OB30 handles periodic tasks that need precise timing, interrupting the main cyclic program to execute at set intervals. |

Introduction

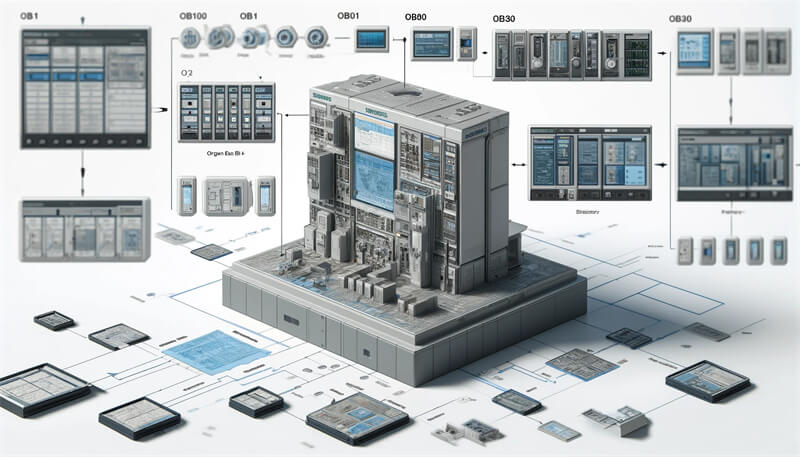

Siemens PLCs are at the heart of modern industrial automation, offering unparalleled reliability and flexibility. One of the critical aspects of Siemens PLC programming is the use of organization blocks (OBs). These blocks serve as the backbone of the PLC’s operational structure, facilitating smooth communication between the operating system and the user program.

Main Types of Organization Blocks

Organization blocks are categorized based on their functionality, ensuring that each task is efficiently managed. The main types include:

1. Main Cyclic OB1

The Main Cyclic OB1 is fundamental to Siemens PLC programming. It cyclically executes the user program, ensuring continuous and reliable operation. Here’s a detailed look at OB1:

- Role and Importance: OB1 manages the cyclic execution of the PLC program, essential for maintaining a seamless operation.

- Creation and Usage: In the TIA Portal, OB1 is automatically created when you add a new PLC project. You can write the entire program within OB1 or call other function blocks (FCs) and function calls (FBs) as needed.

- Example Scenarios: OB1 is ideal for managing repetitive tasks such as monitoring sensors, controlling actuators, and executing control loops.

2. Time Interrupt OBs

Time interrupt OBs are crucial for tasks that need to be executed at specific intervals. These include:

- Overview: Time interrupt OBs, such as OB10 to OB17, are designed to execute tasks periodically, such as every minute, hour, or day.

- Examples of Usage: Typical applications include data logging at regular intervals, updating display screens, and periodic system checks.

- Configuration Steps: In TIA Portal, you can configure the time intervals for these OBs, ensuring they meet the specific requirements of your application.

3. Event-Driven OBs

Event-driven OBs handle specific events that occur during the PLC operation. These include:

- Functionality: Event-driven OBs like hardware interrupts (OB40 to OB47) respond to events such as hardware failures, input changes, and specific program conditions.

- Practical Applications: They are used for tasks such as responding to emergency stop conditions, managing fault diagnostics, and handling user-defined events.

- Configuration and Implementation: Setting up event-driven OBs involves defining the conditions under which they are triggered and ensuring they integrate seamlessly with the overall PLC program.

Start-Up OBs (OB100)

Start-up OBs like OB100 play a vital role in initializing the PLC system. They ensure that the system is ready for operation by performing essential start-up tasks.

- Role and Importance: OB100 is called and executed once when the PLC transitions from STOP to RUN mode, initializing variables and resetting system modules.

- Initialization Tasks: OB100 handles tasks such as recalibrating sensors, checking for alarms, and ensuring all system components are in a safe state before starting the main cyclic execution.

- Example Scenario: An example use case for OB100 is to initialize safety systems and perform self-diagnostics to ensure the system is ready for operation.

Cyclic Interrupt OBs (OB30)

Cyclic interrupt OBs are essential for tasks requiring precise timing. OB30 is one such block that handles these periodic tasks with high accuracy.

Role and Importance

OB30 ensures that specific functions are executed at defined intervals, interrupting the main cyclic program to perform these tasks. This is critical for processes that need exact timing, such as:

- PID Controller Processing: Ensuring precise control of process variables.

- Safety Circuits Monitoring: Regularly checking safety conditions to prevent accidents.

- Monitoring Communication: Managing data exchange between machines to ensure seamless operation.

Configuration Steps

Setting up OB30 involves several key steps to ensure it operates correctly:

- Cycle Time: Define the period between two calls of OB30. This interval must be smaller than the runtime of the OB to avoid overlapping calls.

- Phase Offset: Adjust the start times relative to the cycle time to prevent conflicts with other cyclic interrupts.

- Priority Setting: Assign a priority level to OB30. Higher priority ensures OB30 interrupts other blocks when necessary.

Avoiding Overlaps

When using multiple cyclic interrupts, it’s crucial to manage their timings to avoid overlaps. For instance, if OB30 runs every 10ms and another block runs every 5ms, they might overlap. Using phase offsets can help stagger their execution times, ensuring smooth operation.

Practical Examples and Simulations

Understanding the practical application of OBs can greatly enhance your Siemens PLC programming skills. Here are some real-world examples:

- OB1 Example: In a manufacturing line, OB1 can be used to cyclically check sensor inputs and control actuator outputs, ensuring products move along the line smoothly.

- OB100 Example: For a power plant, OB100 might initialize system parameters and check for any faults before starting the main processes, ensuring safe and reliable operation.

- OB30 Example: In a chemical processing plant, OB30 can handle the precise timing required for mixing ingredients, maintaining strict process control.

Simulation Exercises

Practicing with simulations in TIA Portal can help you understand how OBs work in real scenarios:

- Create a Simple OB1 Program: Set up a program that reads sensor inputs and controls an output based on the input state.

- Simulate OB100 Initialization: Write a start-up routine that initializes variables and checks system status, then simulate the transition from STOP to RUN mode.

- Configure and Simulate OB30: Set up a cyclic interrupt to execute a specific task every 10ms, ensuring it does not overlap with other cyclic tasks.

Expert Tips and Best Practices

To get the most out of your Siemens PLCs, here are some expert tips:

- Optimize OB Usage: Use OBs to segment your program logically, making it easier to read, debug, and maintain.

- Monitor Cycle Times: Keep an eye on the cycle times of your OBs to ensure they stay within acceptable limits, avoiding system slowdowns or failures.

- Use Comments and Documentation: Clearly document your OBs and their functions within your program to aid in troubleshooting and future updates.

Best Practices

- Consistent Naming Conventions: Use clear, consistent names for your OBs to make your code more understandable.

- Regular Testing and Validation: Test your OBs regularly in both simulated and real environments to ensure they function as expected.

- Stay Updated: Keep your knowledge up to date with the latest features and best practices in Siemens PLC programming by referring to Siemens’ official documentation.

Conclusion

Organization blocks are the cornerstone of Siemens PLC programming, providing structure and control over the system’s operations. From the essential Main Cyclic OB1 to the specialized Time Interrupt and Event-Driven OBs, each block plays a crucial role in ensuring your PLC operates efficiently and reliably.

For more in-depth resources and expert guidance, explore our comprehensive range of articles and products at ControlNexus. Whether you’re just starting with Siemens PLCs or looking to deepen your expertise, we are here to support your journey in industrial automation.

Additional Resources

- Comprehensive Guide to Function Blocks (FB) vs. Function Calls (FC)

- Understanding Siemens PLC Data Types

- Mastering Siemens PLC Programming: A Comprehensive Guide to TIA Portal

- Comprehensive Guide to Connecting Your Siemens PLC with an HMI

For further assistance, feel free to contact us. We’re here to help you master Siemens PLCs and enhance your automation solutions.